CHNV Series Two-Stage 3-in-1 Plastic Recycling Machine

Simple in Design. Flexible in Operation

Recycling Processes of Repro-Flex

Our state-of-the-art machines are designed to be user-friendly and efficient.

We offer flexible solutions that adapt to your production needs.

Join us in making sustainable choices for a better future.

Learn MoreApplications

Our customized machines are ideal for various applications:

- Agricultural film recycling

- Post-industrial plastic scraps

- General-purpose waste recycling

- Plastic bag manufacturing for food packaging

- Reusable shopping bags production

- Extrusion and production of plastic sheets

Plastic Waste Film Recycling Machine – YF-ATR-75

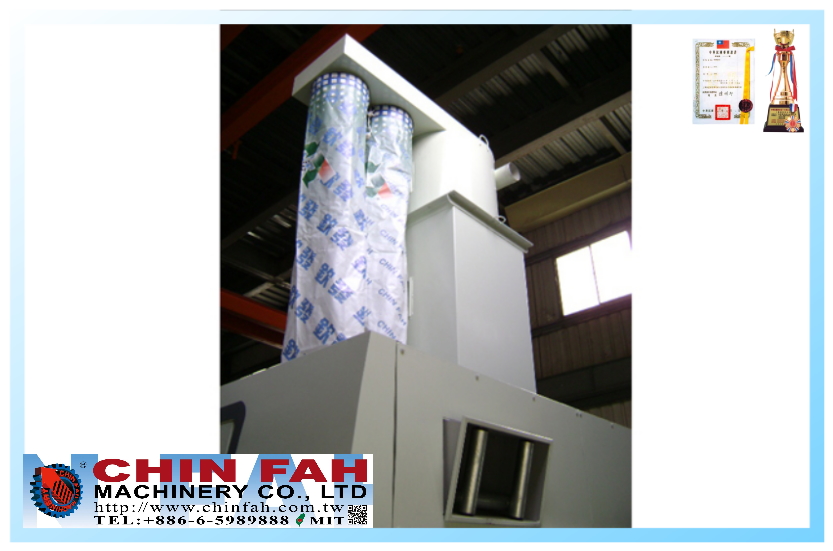

Compact 3-in-1 System for Efficient Plastic Film Recycling

Product Description

- Certified under CE Machinery Directive (1999) for user safety.

- Awarded Second Prize at TAIPEI PLAS 2008 for Plastic Extrusion Machine.

- 3-in-1 feeding system: Conveyor + Crusher + Waste Storage Tank – saves labor and boosts efficiency.

- Ideal for small factories processing clean HDPE/LDPE/LLDPE film waste.

- Air-cooling system – water-saving and easy to operate.

- Eco-friendly design – saves up to 30% on total power consumption.

- Low noise with reliable performance and compact design.

Product Specifications

- Crusher: Shreds plastic into small pieces and sends to storage tank via built-in blower.

- Conveyor: Automatically feeds plastic into crusher – reduces labor costs.

- Storage Tank: Holds shredded film, fed by screw conveyor into cyclone hopper.

- Screw + Inverter: Delivers material from tank to hopper; extruder starts when full – power-saving.

- Forced Feeding Device: Assists plastic feeding into the extruder.

- Venting Extruder: Suitable for inked, foamed, and wet plastic waste. Vacuum pump included for venting.

Note: All specifications and images above are for reference only.

Need more details? Contact us anytime.

E-mail: sales@chinfah.com.tw

| Model | YF-ATR-75 |

|---|---|

| Raw Materials | HDPE / LDPE / LLDPE |

| Cooling Type | Air-Cooling |

| Max. Output | 40–60 kg/hr |

| Die Head Type | Die Face Cutting |

| Product Type | Bean Type Pellets |

| Screw Diameter | 75 mm |

Contact us

If you have any questions or need more information, please feel free to contact us.